Designed to plug directly onto the backplane of Rockwell Automation® CompactLogix 5380 controllers, Hardy HI5069 scale modules enable faster system performance by serving as a co-processer to the control system, delivering post-processed (filtered) weigh data at a rate of 250 updates per second directly to the backplane.

SECURE

Controller-based change detection, device authentication, firmware encryption and event logging help to protect the entire integrated system against malicious intent. A final layer of protection is provided by Common Industrial Protocol (CIP™) Security to prevent attacks commonly carried out over large organizational networks. This provides resiliency of manufacturing operations (Cybersecurity) as a path to Production Excellence.

REDUCE TIME TO COMMISSION

Benefit from tight integration of a scale system by using Add-On-Profiles, Add-On-Instructions and Faceplates available from Hardy and native to Studio 5000 Logix Designer®.

Industries such as Chemical, Food & Beverage, Life Sciences, Metals & Mining, Aerospace, Oil & Gas, and Plastics benefit from the Hardy Productivity Toolbox – C2® calibration and Integrated Technician® scale diagnostics – enabling a proactive maintenance strategy and troubleshooting with the touch of a button.

SIMPLE SET-UP & CALIBRATION

Use load sensors with Hardy's exclusive C2® Calibration for automatic system calibration saving hours in commissioning and routine maintenance. By reading the calibration with certificate embedded electronically in the C2 sensor, the weigh system can be calibrated with the touch of a button.

MAINTENANCE & DIAGNOSTICS

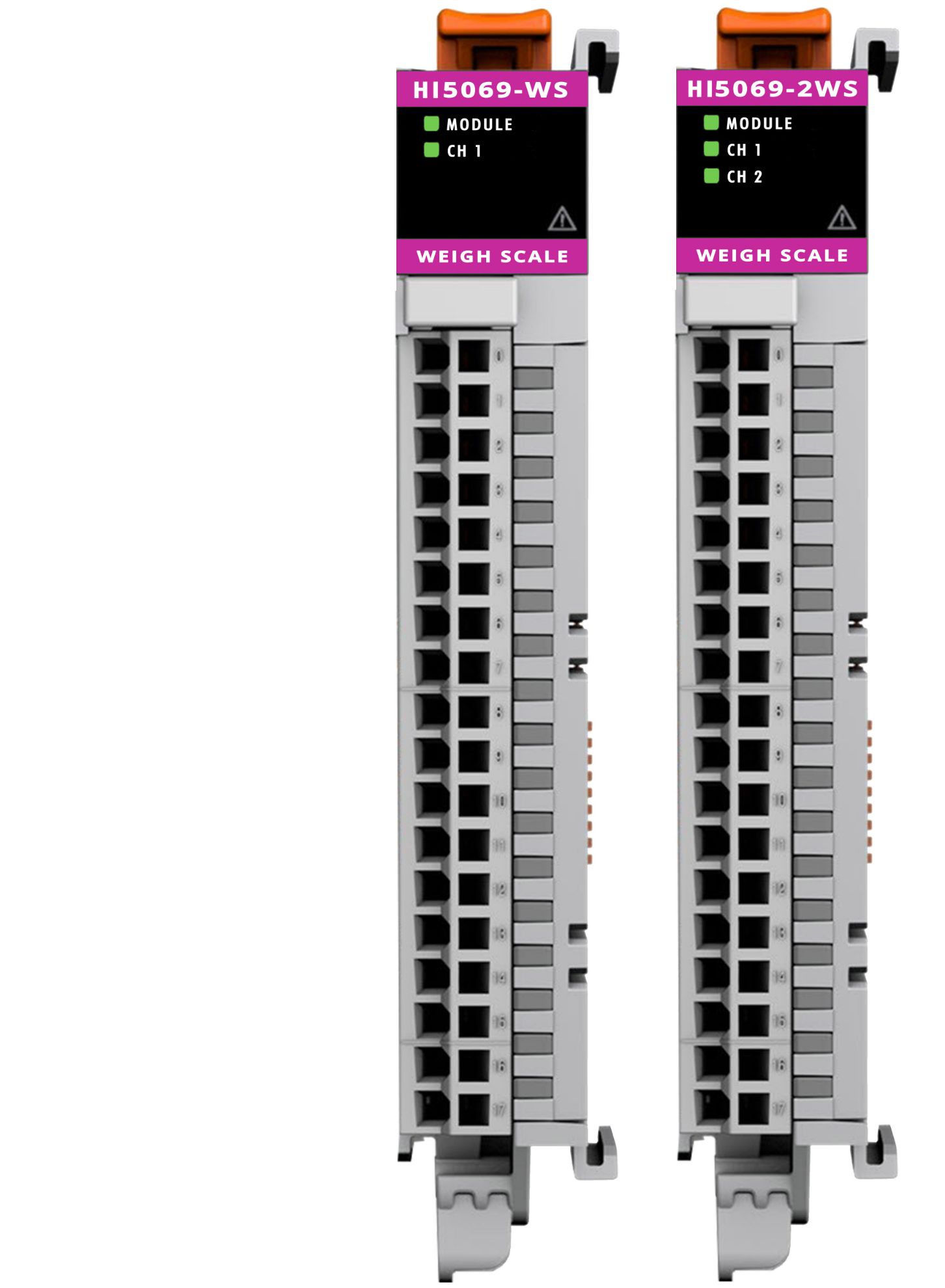

For quick and easy troubleshooting, the HI5069 scale modules feature built in diagnostics that include 3 LEDs per module that indicate Plug-In-Module and weigh scale status. With Integrated Technician®, the module monitors and troubleshoots the weighing system by diagnosing individual sensors without the need to disconnect.

Performance:

Resolution

Stable processed weight 1:10,000

Internal resolution 1:8,388,608

Update rate to backplane: 250 times per second

A/D conversion rate: up to 4800 times per sec

Number of Load Cells:

Up to 8 350 Ω per weight processing channel (1 for -WS and two for -2WS modules)

Modes:

Gross, Net

Units of Measure:

Ounce, Pound, Ton, Gram, Kg, Metric Ton

Weight Processing

WAVERSAVER®: .25 Hz to 7.5 Hz

Averaging:1 to 255 User-selectable in single increments

Calibration Methods:

C2® calibration without test weights

Traditional calibration with test weights

Output:

Excitation 5VDC

Inputs:

Signal, -0.3 mV to +15 mV

Sense, +5 Vdc

C2® Electronic Calibration

Mounting

Directly to Backplane

Recommended Terminal Base Cat# 5069-RTB18-SCREW

Backplane Ratings:

MOD Power: 18-32 VDC, 75 mA

SA Passthrough Max: 10-32 VDC 9.95

Temperature:

Operating: 0 °C -+ 60 °C (32 °F - +140 °F)

Storage: -40 °C - +85 °C (-40 °F - +185 °F)

Humidity:

5-95% non-condensing

Certifications:

Safety: UL & CUL, CE

Environment: RoHS3 and REACH Compliant

Hazardous: Class I, II, III/Div2

Warranty:

Two-year warranty against defects in workmanship

The Hardy Process Toolbox is a set of productivity tools that support industrial weighing functions. Each tool saves time, increases accuracy, improves efficiency, or reduces risk in process weighing applications, including WAVERSAVER® to eliminate vibration, C2® electronic calibration, and Integrated Technician® to name just a few.

The HI5069 modules features the following Toolbox technologies:

C2® (or eCAL) Electronic Calibration

The Hardy C2® (or eCAL as it is known in China) core feature provides quick and easy electronic calibration of a weighing system without the need for heavy test weights.

INTEGRATED TECHNICIAN® Operator Diagnostics

Hardy's INTEGRATED TECHNICIAN (IT) core feature helps you troubleshoot your weighing system and diagnose problems from the front of the instrument or via the PLC. These tests display system weights, voltages, and pass/fail displays to help isolate a problem to the instrument, cabling, or sensors, helping to reduce maintenance costs.

WAVERSAVER® vibration eliminator

Hardy's WAVERSAVER core technology eliminates the effects that surrounding vibration has on the scale weight signal, providing only true data for fast, accurate weight reading.

WAVERSAVER+

A patent pending dynamic algorithm that improves the stability of static weight readings by 3X.