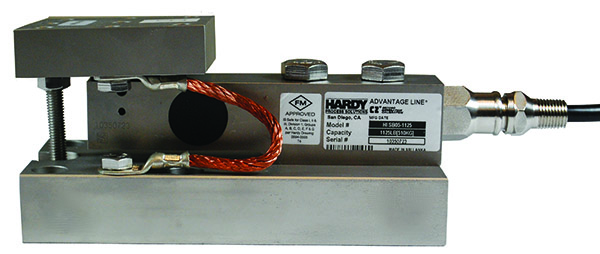

The Hardy HILPS05 ADVANTAGE® Lite Series sliding load cell system consists of stainless steel, mV/V and mV/V/ohm matched HISB05 load sensors and mounts with an IP67 rating and C2® electronic calibration capabilities. The load sensor combined with the bumper, slider, fixed mounting configuration offers durable workhorse performance, along with best-in-class protection from liftoff (6.6 -15.2Klbs) and side forces, and best-in-class accuracy in vibration installations. The bumper slider fixed mount is perfect for agitated vessels, vibratory feeders, and wind-loaded tanks. With hazardous FM approval, this industrial load cell system deliver consistent shear beam performance.

SPECIFICATIONS HIHLPS Mounts

Load Point with Stainless Hardware (-43) or zinc plated Hardware (-45). Shipping Weight approx.10-35 lbs. for Mounts, and 4-17 lbs. for each Sensor.

A vessel with 3 legs will require 1 each fixed (F), bumper (B) & slider (S) assy.

A vessel with 4 legs will require 1 each fixed (F), bumper (B) & 2 each slider (S) assy.

Load points can be ordered as a 3 or 4 load cell system rather than ordering individual components.

lbs mt FIXED BUMPER SLIDER Part #

1,125 0.5 F B S HILPS05-1125-4__

2.25K 1 F B S HILPS05-2.25K-4___

4.5K 2 F B S HILPS05-4.5K-4___

11.25K 5 F B S HILPS05-11.25K-4___

22.5K 10 F B S HILPS05-22.5K-4___

CAPACITY MODEL# 3 POINT LOAD CELL SYSTEMS

lbs mt Part #

3,375 1.5 HI3S05-3375-4__

6.75K 3.1 HI3S05-6.75K-4__

13.5K 6.1 HI3S05-13.5K-4__

33.75K 15.3 HI3S05-33.75K-4__

67.5K 30.6 HI3S05-67.5K-4__

CAPACITY MODEL# 4 POINT LOAD CELL SYSTEMS

lbs mt Part #

4.5K 2.0 HI4S05-4.5K-4__

9K 4.1 HI4S05-9K-4__

18K 8.2 HI4S05-18K-4__

45K 20.4 HI4S05-45K-4__

90K 40.8 HI4S05-90K-4__

SPECIFICATIONS HISB05*

Capacity lbs 1125/2250/4500/11250/22500 lbs

Capacity kg 510/1020/2040/5102/10206 kg

Rated Output (ES) 2±0.002mV/V

Non-Linearity <±0.0166 % R.O.*

Hysteresis <±0.0166 % R.O.*

Zero Balance <±5.0 % R.O.*

Combined Error <±0.02 % R.O.%*

Creep @ 30 Min. <±0.0166 % R.O.*

Temp Effect Output ±0.0127 % R.O./C*

Temp Effect Sensitivity ±0.010 % R.O./C*

Input Resistance 1100±50 ohm

Output Resistance 1000 ± 2 ohm

Insulation Resistance ≥5000 Mohm

Excitation 5 - 15 vdc

Safe Load Limit 200 % Emax

Ultimate Load 300 % Emax

Safe Side Load 50% Emax

Approvals NTEP Class III, RoHS 3, REACH

Hazardous FM IS Class I, Div I

Protection EN 60 629 IP67

Warranty

Two years

* HI SBH05 in 22.5Llb capacity ONLY

• Non-Linearity ±0.0400% R.O

• Hysteresis ±0.0400% R.O.

• Combined Error ±0.0500% R.O.

• Creep error @30 Min.±0.0600% R.O.

• Temp Effect Ouput ±0.0400% R.O./10°C

• Temp Effect Sensitivity +0.0200% R.O./10°C

The Hardy Process Toolbox is a set of productivity tools that support industrial weighing functions. Each tool saves time, increases accuracy, improves efficiency, or reduces risk in process weighing applications, including C2® electronic calibration, and Integrated Technician® to name just a few.

Hardy load cells support the following Hardy Process Toolbox functions when coupled with a Hardy Instrument and Hardy C2® cable.

C2® (or eCAL) Electronic Calibration

The Hardy C2® (or eCAL as it is known in China) core feature provides quick and easy electronic calibration of a weighing system without the need for heavy test weights.

INTEGRATED TECHNICIAN® Operator Diagnostics

Hardy's INTEGRATED TECHNICIAN (IT) core feature helps you troubleshoot your weighing system and diagnose problems from the front of the instrument or via the PLC. These tests display system weights, voltages, and pass/fail displays to help isolate a problem to the instrument, cabling, or sensors, helping to reduce maintenance costs.