HI 6500 Series Now Include Extreme Version with 6X the Speed and 3X the Resolution

The HI 6500 series are EtherNet/IP® enabled weight processors with a Rockwell Add-On-Profile (AOP) and Faceplate/AOIs. They have a big, bright multi-channel display and deliver fast, high-resolution weight readings. They also feature Modbus, Analog, and Ethernet communication options.

Book a One-on-One Virtual Demo to See the HI 6500 in action!

Take the HI6500 for a Test Drive

Weight processors are used as front ends to control systems or standalone for all types of general weighing applications. Operating blind or with a display, they measure, condition, and communicate weight without any need to control.

SOLID PERFORMANCE

The HI 6500 series delivers stable processed weight with a resolution of 1:10:000, and an update speed of 110 updates per second (processor, display, and comm.). They enhance the productivity of process manufacturing systems where fast, precise weight-based controls are critical. They offer you many communication choices including EtherNet/IP, Modbus TCP) & Modbus RTU, and Analog 4-20mA.

EXTREME WEIGHT PROCESSOR

The HI 6500-XP Extreme Weight Processor can process and output 660 updates per second of processed (stable) weight with a resolution of 1:30,000. The HI 6500-XP represents the state-of-the-art in processing uniformity and speed. A/D conversion, weight processing, and the communications port ALL update at 660 times per second, providing the PLC with the latest processed weight reading every 1.5 milliseconds. Many competitors’ products execute the A/D conversion at one frequency, then process the weight and communications ports at a much slower rate typically 20 to 50Hz, only providing the PLC with an update every 20 to 50 milliseconds. The HI 6500-XP results in better product consistency and product yields while reducing processing time, waste time, and materials. It is designed for applications where speed and accuracy are paramount to control and quality, such as batching, blending, filling, dispensing, and check weighing.

INSTALLATION YOUR WAY

For panel mounting, simply drill five holes to mount the keypad/display on the front and the instrument to the other side. For blind or remote mounting, just snap its built-in clip onto a DIN rail or mount on a wall. The HI 6500 series fits in a 2" deep cabinet!

EASY TO READ

For maximum visibility and usability, the HI 6500 series features a big, rugged high-contrast display with a 140 degree viewing angle for easy reading at a distance. Discrete status messaging means there is no need to check a manual for error codes or instructions.

MULTI-CHANNEL DISPLAY

To save space and energy, the HI 6500 series can deliver the weight readings of up to four instruments on one big, bright display panel simultaneously! Name your display inputs for easy ID and rearrange them in any order.

LOW POWER CONSUMPTION

Each instrument consumes just 5 watts nominal and 7 watts max, saving energy costs while driving up to 8 load points and two Hardy IT Junction Boxes. Share a keypad/display with four instruments and save 1.5 watts more per blind unit.

EASE OF SET-UP & CALIBRATION

A set-up wizard guides you through installation and calibration, or use the embedded web server to set up parameters from anywhere on your network. Front panel keys and simple menus enable quick, easy setup with supporting help text. Use Hardy's exclusive C2® for automatic system calibration, which saves hours of start-up and maintenance time. A Rockwell Add-On-Profile makes PLC setup fast and easy.

INTEGRATED TECHNICIAN®

Quickly and easily troubleshoot the weighing system from the front panel of the display or connected control system using Hardy's proprietary INTEGRATED TECHNICIAN (IT) built-in system diagnostics.

VIBRATION IMMUNITY

Hardy’s WAVERSAVER® technology suppresses vibration and mechanical noise, dramatically reducing scale settling time and increasing the speed of stable gross and net weight readings. Exclusive to the HI 6500-XP Extreme Weight Processor is Hardy’s patent-pending WAVERSAVER+® technology that suppresses vibration and mechanical noise, reducing scale settling time and increasing the speed of stable gross and net weight readings.

HI 6500 Series in a Swivel Mount Enclosure

The Hardy Swivel Mount Enclosure is designed to withstand the most demanding industrial environments. Made in the USA using 16-gauge Stainless Steel, the enclosure is rated for IP66/NEMA4X environmental conditions and is delivered containing a Hardy HI 6500 series weight processor. The large, high-contrast LCD display that makes the instrument easy to view and simple to use is protected from impact by a polycarbonate window behind a water-tight membrane. The tactile button cluster in the display eliminates accidental triggering caused by wipe-down sanitizing and harsh water-jet cleaning.

Hardy HI 6500 series weight processor. The large, high-contrast LCD display that makes the instrument easy to view and simple to use is protected from impact by a polycarbonate window behind a water-tight membrane. The tactile button cluster in the display eliminates accidental triggering caused by wipe-down sanitizing and harsh water-jet cleaning.

SIMPLE INSTALLATION

Featuring an extra-large base, the Hardy Swivel Mount Enclosure can be permanently mounted on both vertical and horizontal surfaces or simply left free-standing on a table top. The swivel mount base installs with just 4 mounting holes that match Hardy’s bench and floor pedestals, leaving plenty of solid surface area to drill a custom hole-pattern that suits any specific installation requirements.

EASY SETUP AND CALIBRATION

The HI 6500 SME comes with Hardy’s Setup WIZARD that guides users step-by-step through instrument set up and calibration. Use Hardy’s C2 sensors for automatic system calibration and scale verification to save hours in commissioning and routine maintenance.

The high-definition LCD display with a 140 degree viewing angle makes instrument use easier than ever with Help Text available at the press of a button. Use the Hardy embedded Webserver to remotely monitor, diagnose, or control your instrument from anywhere on your network.

LOW POWER CONSUMPTION

Each instrument consumes just 5 watts nominal and 8 watts max, saving energy costs while driving up to 8 load points.

HI 6500 Series in a Panel Mount Wall System

REDUCE YOUR TIME TO DESIGN, DEVELOP AND DEPLOY

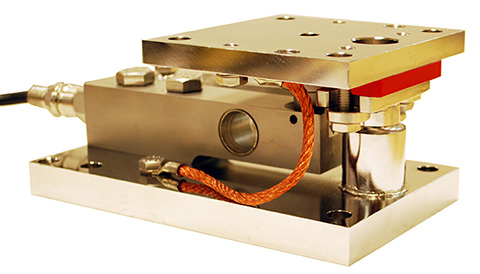

The Hardy HI 6500 series of weight processors are now available factory installed in a stainless steel (Nema 4x) enclosure with an IP66 rated display panel. With a built in summing card, the Panel Mount Wall System (PMWS) eliminates the need for a system junction box.

factory installed in a stainless steel (Nema 4x) enclosure with an IP66 rated display panel. With a built in summing card, the Panel Mount Wall System (PMWS) eliminates the need for a system junction box.

EASY INSTALLATION

Just hang it on the wall, connect your load cells to the built in summing card and you are ready to calibrate! The PMWS eliminates the following headaches:

- What is the best size of box to use?

- Where do I need to drill holes?

- What size of glands should I use?

- Do I have the right washers and fittings?

- Do I have enough room for cables?

- Where do I position the summing card?

- Do I have the right tools? Punch kit?

SIMPLE SET-UP & CALIBRATION

Each PMWS comes with with a keyboard and display for easy instrument access. The embedded webserver in the weight processor enables access to setup and calibration from anywhere on your network. The display adds front panel keys, simple menus and help text to make local control elementary. Use Hardy's exclusive C2® for automatic system calibration to save hours in commissioning and routine maintenance.

QUICK MAINTENCE & DIAGNOSTICS

Use INTEGRATED TECHNICIAN® to maintain and troubleshoot the weighing system from anywhere in the world or use Hardy’s intuitive local display. Store all the system parameters on a USB, clone settings between channels, and restore settings with the press of a button. Quick-disconnects on all wiring makes replacing a damaged load point a snap!

Save Time and Money with a Preconfigured Wall Mount Solution!

Specifications HI 6500, 6510, 6500-XP, and 6510-XP, SME and PMWS

Resolution HI 6500 and HI 6510

- Stable processed weight 1:10,000

- Maximum displayed resolution: 1:999,999

- Internal resolution 1:8,388,608

Resolution HI 6500-XP and HI 6510-XP

- Stable processed weight 1:30,000

- Maximum displayed resolution: 1:999,999

- Internal resolution 1:8,388,608

Update Rate HI 6500 and HI 6510

- Processed weight, display, communications: 110 times per sec.

- Unprocessed weight (A/D conversion): 4800 times per second

Update Rate HI 6500-XP and HI 6510-XP

- Processed weight, display, communications: 660 times per sec.

- Unprocessed weight (A/D conversion): 4800 times per second

Modes

- Gross, Net, Piece Count

- HI 6300 Emulation Mode

Units of Measure

- Ounce, Pound, Ton, Gram, Kg, Metric Ton, Pieces

Weight Processing

- WAVERSAVER®: .25 Hz to 7.5 Hz

- HI 6500-XP and HI 6510-XP ONLY: WAVERSAVER+® Adaptive Filtering

- Averaging:1 to 255 User-selectable in single increments

Display

- 80:1 contrast ratio with 4.3" effective viewing area

- 140° viewing angle

Multi-channel Display

- Control, configure, and view one to four instruments on a single front panel (up to 3 blind and one with a display)

Calibration Methods

- C2® calibration without test weights

- Traditional calibration with test weights

Excitation

- 5VDC

Number of Load Cells

- Up to 8 at 350 Ω with two IT junction boxes

Keypad

- 5-Button Tactile

Mounting

- DIN, low profile, panel, wall

Communications

- EtherNet/IP (-EIP models)

- Ethernet UDP

- Ethernet TCP/IP(Embedded Webserver)

- Modbus RTU

- Modbus TCP (-EIP models)

- Analog 4-20mA (HI 6510 models)

Communication Interface

- Terminal, RJ-45

- USB Secure Memory Module for saving setup and configuration

Power

- 12-27 VDC

- 5 watts nominal with display

- 7 watts max with two Hardy IT junction boxes and 8 load points

Temperature

- -10°C to +60°C (14° F to 160°F)

Humidity

- 0-90% non-condensing

Dimensions

- 7” W x 3”H x 2 ¼” D (18 cm x 7.6 cm x 5.7 cm)

Certifications

- Hazardous: Class I, II.III/Div2

- Safety: CE, UL & CUL

- EtherNet/IP ODVA Certification Level 3

- RoHS3 and REACH

Warranty

- Two-year warranty against defects in workmanship

Specifications Swivel Mount Enclosures

Enclosure

- IP66/NEMA 4X tested

- 16 gauge 304 Stainless Steel

- Bisco HT-840 Gasket

- NEMA 4X Nylon Cable Glands

Power

- 24 VDC / 7 watts max with two IT junction boxes and 8 load points

- 100-240 VAC / maximum 8.25 Watts (optional)

Temperature

- -10°C to +50°C (14° F to 122°F)

Humidity

- 0-90% non-condensing

Dimensions

- 7” W x 6”H x 5” D (23.5 cm x 15.2 cm x 12.7 cm)

Cable Grip Range

- 0.17” to 0.45” diameter (0.4 cm to 1.1 cm)

Specifications Panel Mount Wall Systems

Enclosure

- Stainless Steel

- Latched opening with hinged lid

- Display tested to IP66 conditions

- Room for excess C2 cables and 120VAC converter

Number of Load Cells

- Up to 8 at 350 Ω

Impedance Range

- 0-10 Ω

Connector Type

- Phoenix Terminal Block

- 7 pin, 1 row, 3.5 mm pitch

Excitation

- 5VDC

Power

- 12-26 VDC

- Up to 7 watts nominal per weight processor

Max Current

- 180mA at 250'

- Max Current/Load Cell: 80mA

Wire Diameter

- 22-24 AWG

Dimensions

- 6.0” D x 8.0”H x 10.0” W

Trim Pots Num Turns

- 11 (for use in non-C2 applications)

Mounting

- Wall mount or DIN rail

Temperature

- -10°C to +60°C (14° F to 160°F)

Humidity

- 0-90% non-condensing

Certifications

- Hazardous Class I,II,III/Div. 2

- UL, CUL, CE

Warranty

- Two-year warranty against defects in workmanship

The Hardy Process Toolbox is a set of productivity tools that support industrial weighing functions. Each tool saves time, increases accuracy, improves efficiency, or reduces risk in process weighing applications, including WAVERSAVER® to eliminate vibration, C2® electronic calibration, and Integrated Technician® to name just a few.

The HI 6500 series features the following Toolbox technologies:

WAVERSAVER® vibration eliminator

Hardy's WAVERSAVER core technology eliminates the effects that surrounding vibration has on the scale weight signal, providing only true data for fast, accurate weight reading.

HI 6500-XP and HI 6510-XP ONLY

Hardy's patent-pending WAVERSAVER+ patent pending adaptive algorithm selects from a bank of 7 noise filters and uses the optimum mix to provide a stable weight under static conditions.

C2® (or eCAL) Electronic Calibration

The Hardy C2® (or eCAL as it is known in China) core feature provides quick and easy electronic calibration of a weighing system without the need for heavy test weights.

INTEGRATED TECHNICIAN® Operator Diagnostics

Hardy's INTEGRATED TECHNICIAN (IT) core feature helps you troubleshoot your weighing system and diagnose problems from the front of the instrument or via the PLC. These tests display system weights, voltages, and pass/fail displays to help isolate a problem to the instrument, cabling, or sensors, helping to reduce maintenance costs.

Embedded Web Server

Access your instrument from any computer browser, easing setup and making diagnostics fast and easy. Use the Embedded Web Server to set up all parameters from anywhere on the Ethernet network.

Secure Memory Module

Hardy's Secure Memory Module (SMM) uses a standard USB memory stick to save configuration data for backup to a PC or to transfer to another instrument.