New Modernized HI6501 Weight Processor

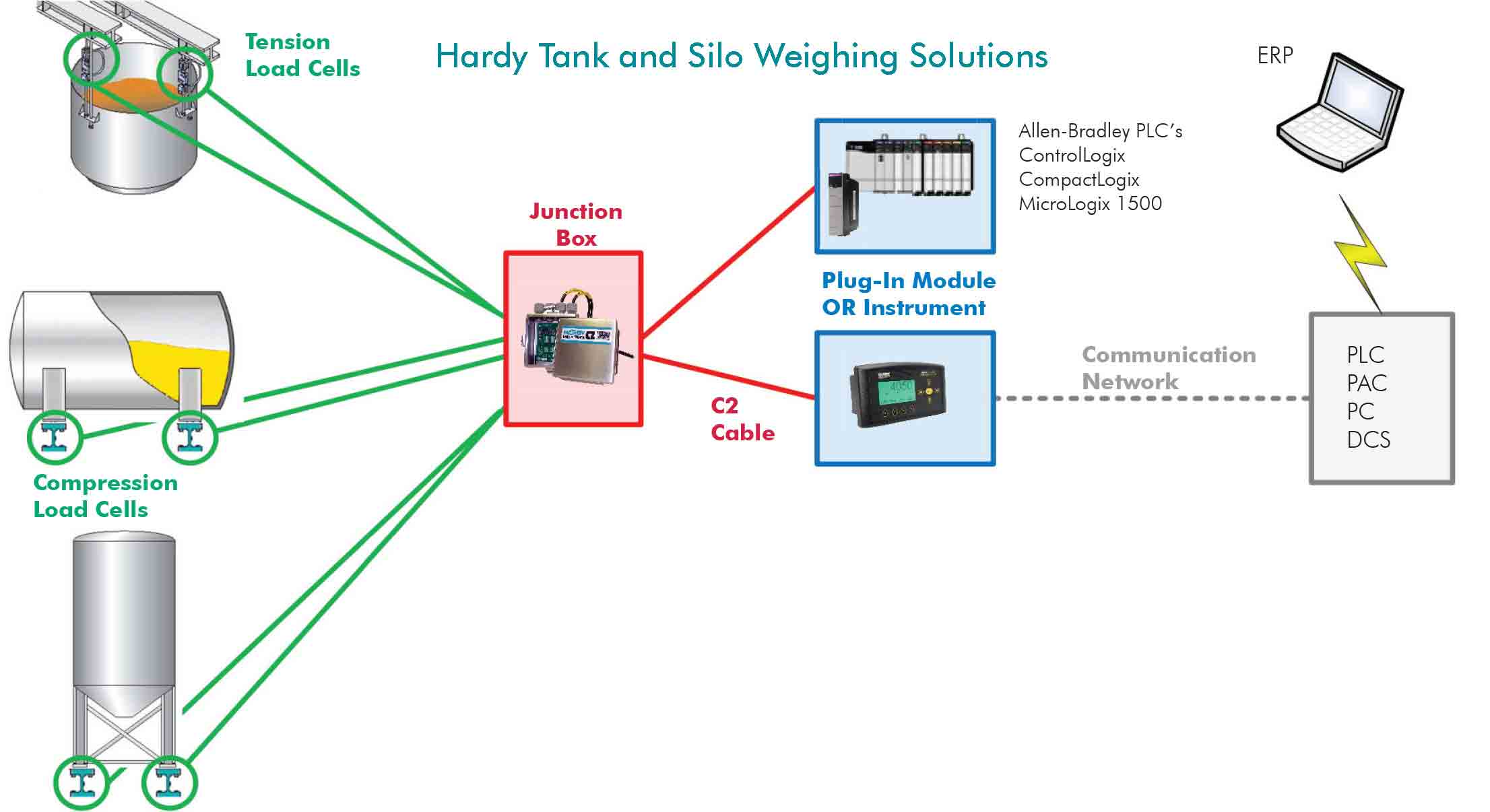

Learn More!There are many factors to consider in vessel weighing such as size, type of vessel, support structure, piping, movement, and environmental (temp, wind, etc) to name a few.

To weigh a vessel using compression it must be entirely supported by load points (load cell with associated mounting hardware). For example, the vessel would have a load point assembly under each leg. If the vessel's location is outside it should have a minimum of four load points to ensure its stability. Indoors, a three load point configuration is acceptable as long as the vessel does not have an associated mixer or agitator.

Skirted silos require a frame to be constructed under them to transfer the weight to four or more load points. Horizontal vessels can sit on saddles that are retrofitted with load points to accommodate vessel expansion and contraction with changes in temperature.

By hanging internal vessels above floor level, valuable production space can be saved with the use of load points in tension. Factors to consider include vessel agitation, center of gravity, and vibrations due to its contents as well as the support structure and piping.

Hardy products for weighing vessels and silos are easy to install, configure, commission, operate, and maintain. They are generally safer and save you time money, raw materials, and/or finished product. Visit our case studies or contact one of our application engineers for a free consultation.